Machine Mastering, a subset of AI, is also used in CNC machining to improve precision. By examining historic details and recent conditions, machine Mastering models can forecast Device don and improve machining parameters. This predictive functionality extends the life of cutting tools and minimizes downtime.

AI can without a doubt application a CNC machine, leveraging State-of-the-art algorithms to automate and enhance numerous components of the programming method.

Modern CNC programming is not restricted to static toolpaths and handbook operator tweaks. With the emergence of AI-driven CAM, manufacturers can harness machine Discovering algorithms that modify toolpaths in serious time, predict routine maintenance requirements, and refine cutting parameters for much better efficiency.

Among the list of principal strategies AI lessens costs is by predicting machine failures. Watch machine general performance in serious time and use AI algorithms to investigate the information and optimize routine maintenance schedules.

Find out how AI and CNC machines are transforming production. Discover the 7 crucial developments that should impression your machine store’s productivity, profitability, and competitiveness in 2025 and over and above.

Regularity and Repeatability: These machines offer regular and repeatable success, essential for prime-quantity production operates.

Ahead of we dive in the AI section, let us immediately recap what CNC machining is. CNC means Pc Numerical Control, and it's a production approach wherever pre-programmed Laptop or computer software dictates the motion of manufacturing unit tools and machinery.

Wherever AI is available in is in using the figures, relaying them straight to machine operators and the machines by themselves, and automatically suggesting efficiency variations, timing alterations, and production improvements to ultimately increase overall throughput.

CNC milling can be a subtractive producing approach-it starts off with a block of material and cuts absent portions of it to kind the finished aspect. Because of this, There exists additional content wastage in CNC milling than in additive manufacturing processes, for instance 3D printing.

When a third axis (Y) is added perpendicular to X and Z, curves could be machined. These are typically pushed by ball screw actuators. The Y-axis slides on linear guides or box strategies. Lots of manufacturers have included other means to maneuver the tools, evolving The three-axis machine into turning centers to get additional descriptive.

Business people all over the world are looking to meet the challenge of evolving customer needs. Buyers want significant-high-quality products, and they want them now, putting producing engineers under pressure to Here balance quality and efficiency in their functions. Integrating AI has significant financial benefits for business owners, including:

With the customizable possibilities that are available, you will find just what exactly will satisfy your unique wants. Most of all, all of MultiCam's lasers are calibrated applying certified equipment so that you can supply the best degree of precision.

And these systems will be able to detect anomalies in machine actions like abnormal vibrations, or variations in temperature or electrical power comsumption, which could issue to an implied failure.

These machines are important for manufacturing superior-excellent components throughout different industries, from automotive to aerospace. Below, we spotlight the main characteristics of CNC mills and CNC lathes, supply a comparison desk, and examine their purposes in modern machine retailers.

Jennifer Grey Then & Now!

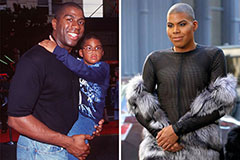

Jennifer Grey Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now! Ryan Phillippe Then & Now!

Ryan Phillippe Then & Now!